Sometimes you just gotta make a guy. per Hokusai, 4″x5″ copper and cherry

Sometimes you just gotta make a guy. per Hokusai, 4″x5″ copper and cherry

Just futzing around without any specific goal in mind, which tends to result in a lot of odd one-off pieces that are extremely annoying to find an actual use for. I have no idea what to do with this opal but it better be something.

People keep claiming I used to be good at this, I do not recall it and evidence is not bearing them out. I do remember that an a proper anvil is not supposed to go “clunk” when you hit it

Taking a class from a master coppersmith at the Arts and Crafts Conference and man have I been overcomplicating this. There’s something intensely satisfying about any craft that can be done well wherever there’s a nail and a hard surface.

Re-setting the stone in my first and probably last attempt at designing for gold.

The goofy two-sided setting has to be pressed on with a fair bit of force, the cool-looking inclusions on this aquamarine were the parts least inclined to tolerate being crushed in a vise, and there’s a limited number of times I can do this before it messes the whole ring up so for a few years now I’ve been serially exploding rocks until I got this impractically oversized one to hold up. Figure we don’t wear these on the job anyway so it won’t matter, we’ll see how long before it snags on something and pops out but it took the buffer trying to eat it pretty well

Greene and Greene styling is genius, looks fancy but extremely simple to replicate with a table saw and mortising chisels. The hardest part of these approximate Blacker House hanging sconces was sourcing the mica shade material.

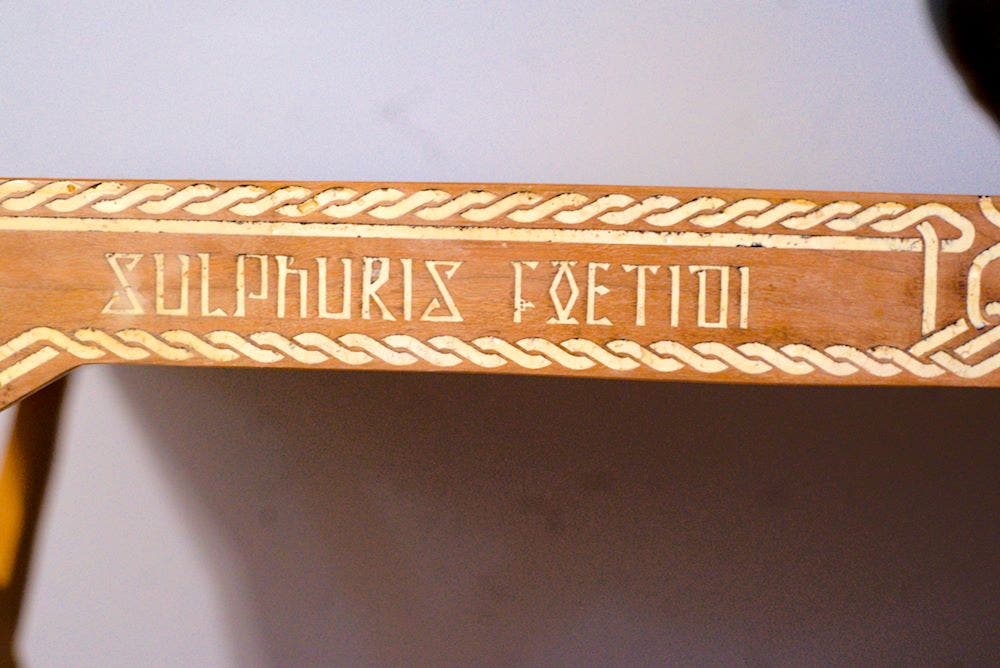

I wanted to follow up on this project once I’d gotten a picture of how it will look longterm, it’s been six months in and out of conditioned spaces and looks exactly like it did six days after finishing so I guess this is it.

The yellow coloration has faded slightly to more of an off-white. Not quite the red-and-cream I’d envisioned initially, it’d look better on a darker wood substrate (and seems at least initially to reject wood stains, so there’s options there), but much less garish than it was in the first week. Within hours of cooling the sulfur had formed a spiderweb of dark cracks throughout (possibly stained by fine sawdust from sanding shortly after?), more dramatic wherever it was shallower/thinner, but apparently still stable. Through months of riding around the east coast in the back of a pickup truck it only ever lost one chunk in the first couple weeks, shown above. Even where I stupidly let the design run over an edge (like on the pull tabs below) it’s holding very fast to the substrate material. I’d still rate it a lot less suitable for any surface that’s going to see wear than the 1/8″ wood inlays I’ve been doing previously, but mostly because I’ve come to a new appreciation of just how goddamn tough Titebond really is. Assuming this stuff continues to hold more or less indefinitely I can live with the cracking, it gives the whole thing a nice aged ivory look – the main visual defect I will have to contend with are the bubbles that formed on casting and never really went away, no matter how much I heated or sanded or tried to fill in. Something like a vibrating table may help to shake them loose while the sulfur is still molten in the future, will have to experiment.

Compared to poured epoxies (and most other goop I’ve seen used for inlays) molten sulfur is both very thin and, once cooled, very opaque, leading to it visibly peeking out of any void including just the pores of the wood. Great for extremely fine detail, a killer on porous woods like oak or mahogany. On the cherry here I had only a few places I couldn’t mop up adequately with a few passes of a heat gun and paper towel but I hadn’t noticed this tendency in the early pieces I did and it made a mess here for a while.

It’s also very visible where I didn’t completely sand off any spillover:

It’ll be a while before I’ve rebuilt enough of my shop to really apply any of this on a new piece, but I should be able to pull off some cool effects playing more to its characteristics in the future rather than treating it like smelly epoxy.

Got this citrine point at a roadside stall in New Mexico; it’s a fun little piece to work with but I haven’t had luck finding more, suppose I’ll have to make them at some point

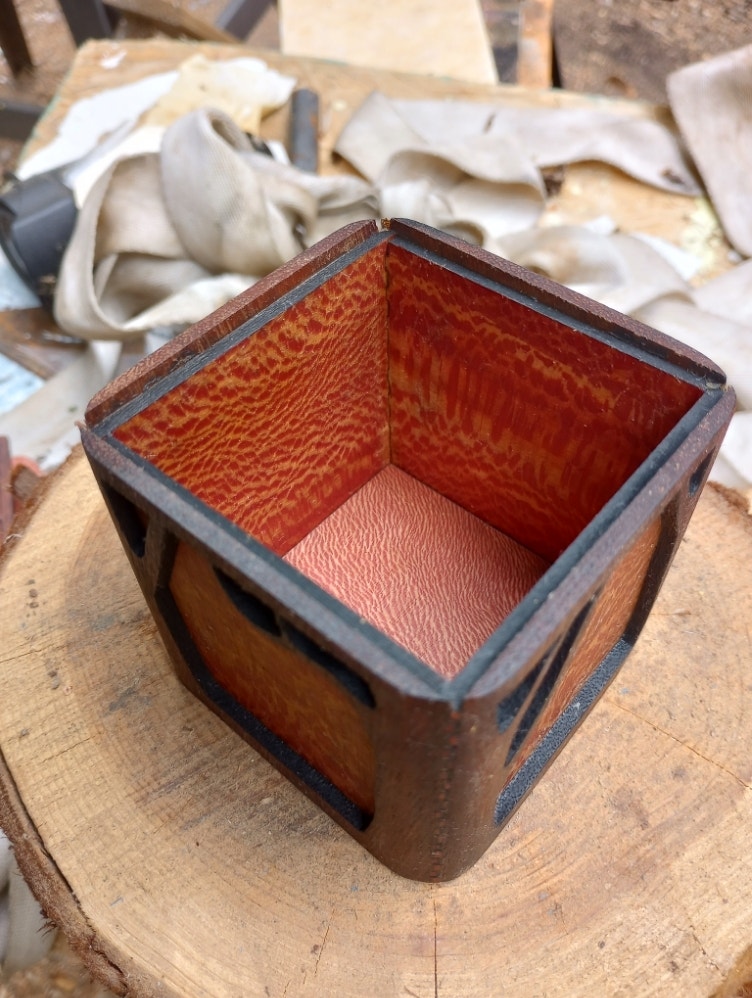

colormatching the sky without dyes used to be a lot harder. need to do something with the lid, it’s just a standard one pulled off another design but doesn’t match the rounded edges on these at all

A sage once told me there’s a rule of thumb for when a piece is completely finished: when you’re sick of looking at it, it’s time to ship